Get the most out of your milling system

MillBox

The simplest Dental CAM software

MillBox ECO

MillBox STANDARD

MillBox EXPERT

Choose the best version for your requirements

|

MillBox Eco |

MillBox Standard |

MillBox Expert |

||

|

Tipologia |

Protesi Cementata |

|

|

|

|

Protesi Ibrida |

|

|

|

|

|

Modelli e Monconi |

|

|

|

|

|

Bite & Guide Chirurgiche |

|

|

|

|

|

R.P.D. |

|

|

|

|

|

ProtesiTelescopica |

|

|

|

|

|

Protesi Avvitata |

|

|

|

|

|

Protesi Mobile |

|

|

|

|

|

Sovrastrutture |

|

|

|

|

|

Taglio Allineatori |

– |

– |

|

|

|

Materiali |

Fresaggio Blochetti |

|

|

|

|

Fresaggio Premilled |

|

|

|

|

|

Fresaggio Dischi a Secco |

|

|

|

|

|

Fresaggio Dischi ad Umido |

|

|

|

|

|

Fresaggio Dischi Metallo |

NO |

|

|

|

|

Moduli aggiuntivi |

N°Assi |

5 |

5 |

5 |

|

Intelligenza Artificiale |

|

|

|

|

|

Modulo Comfort |

|

|

|

|

|

Modulo Advanced |

|

|

|

|

|

SUM3D Aperto |

NO |

NO |

|

|

|

Strategy Editor |

NO |

|

|

|

|

Make&Mill ® |

NO |

|

|

|

Additional modules

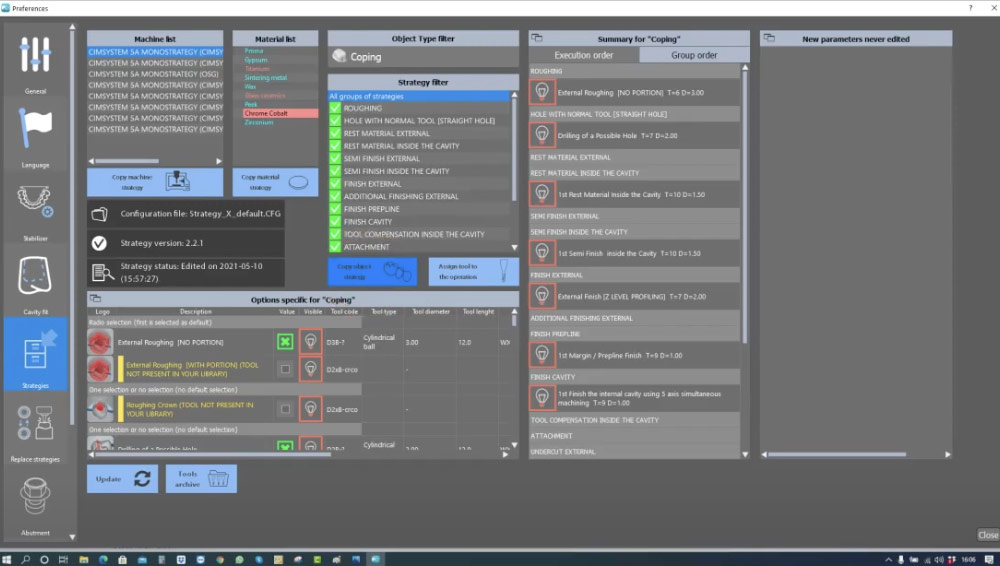

Strategy Editor

The new configurator is an unprecedented improvement in strategy management. It allows you to both select and duplicate predefined strategies as a basic user and access and create fully customised strategies as an expert user, all according to your specific needs. In both cases, the strategy will automatically grow and be updated in line with the software, freeing you from the need to modify, test and fine-tune it each time. What’s the benefit? Saving time and resources putting you at the forefront of dental manufacturing innovation.

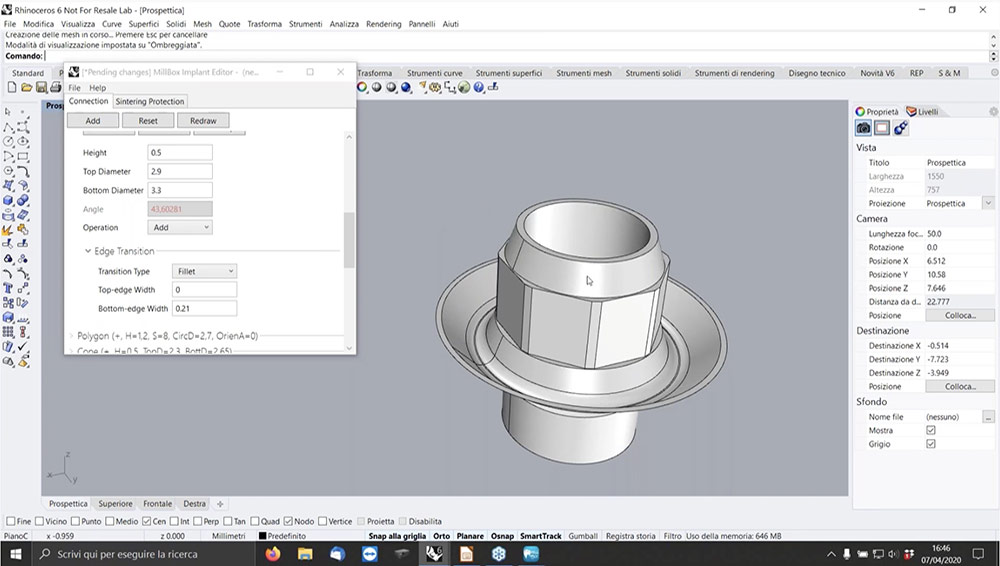

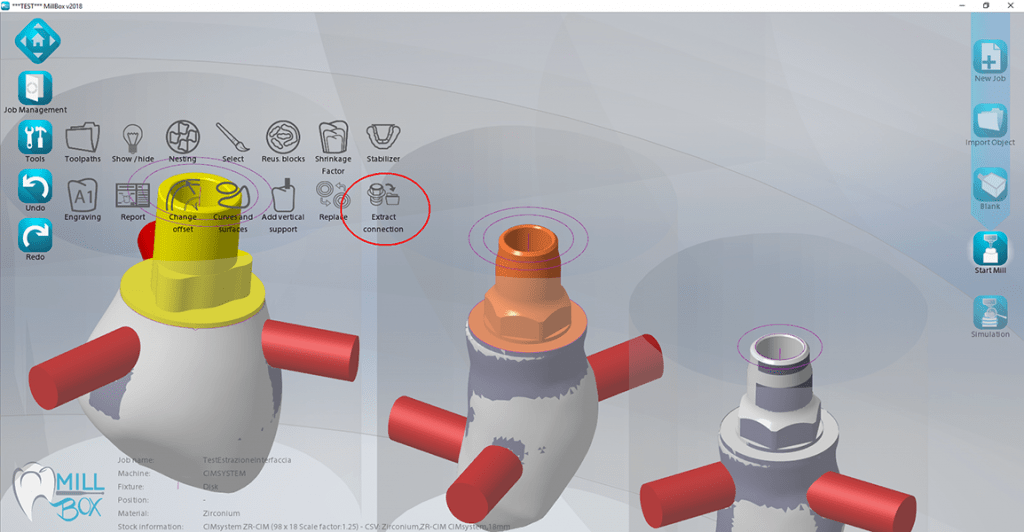

Implant connection editor

Using Implant Editor, you can easily create customised implant connection shapes. The software guides you through the design of the shape step by step, through basic shapes. Optimised connection guards can be designed to reduce both milling time and excessive tool use. The CAD element can be automatically imported into MillBox with a perfect adaptation of settings and parameters. With Implant Editor, you have unparalleled freedom to design and save your library, and creating shapes will no longer be a problem.

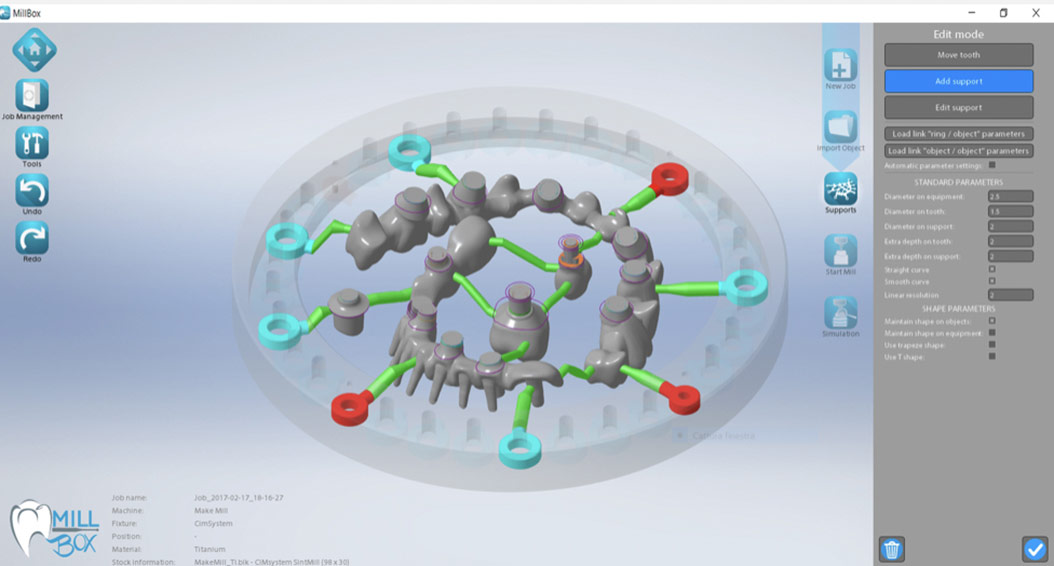

Make&Mill

Available as a module of MillBox, Make&Mill allows two technologies – additive and subtractive – to be used within a single application. Having created the object with additive technology, in sintered metal or resins, the Make&Mill solution allows the object itself to be milled. The advantage is twofold: additive technology ensures economy and less operator input, while subtractive technology brings precision, refining the surfaces of the manufactured object.

Comfort module

•Reduce the cavity axis

•Change the angle of the axis hold

•Import multiple STL files STL

•Shading of undercuts in areas touching the pin

•Full kinematic

simulation

•Automatic blank selection

•MillBox supports bar-code printing and scanning

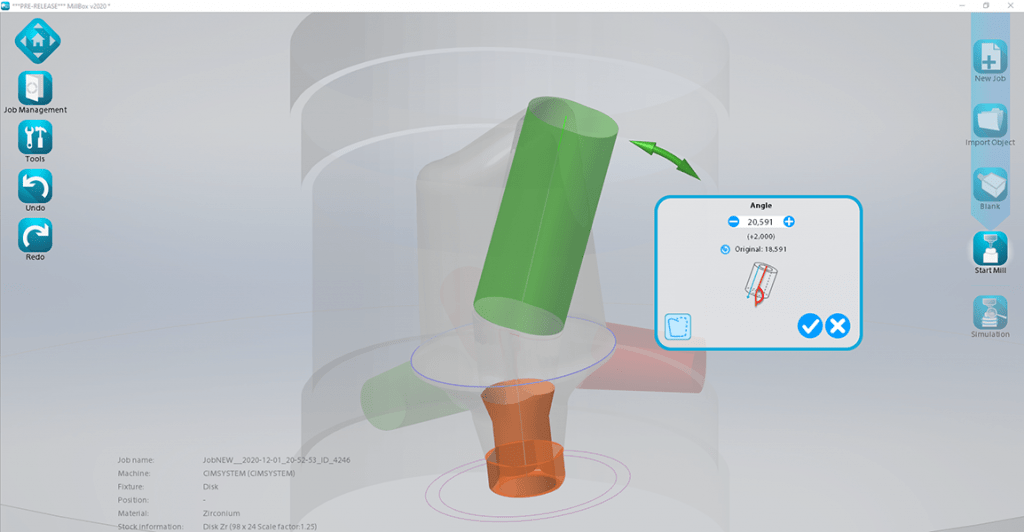

Advance module

•Milling only certain objects

•Interface import

•Interface extraction

update

•Change of axis/angle of angled

hole

Main software functions

Multi-layer materials

All materials currently used in dentistry can be managed in MillBox, with the option of displaying the colour of the material in use and its gradation. It is also possible to use and create “shaded” and “multilayered” materials, allowing the user to place and move the element in the most appropriate position, thanks to the display of different colours.

Main software functions

Abutment Fit

If the fit does not meet the dental technician’s requirements, it is possible to adjust the friction between the abutment and analogue with the abutment fit, without having to reshape the object completely.

Main software functions

Element setting

With MillBox, it is possible to import any type of dental element (crown, bridge, etc.) from any CAD source. Recognition of the type and morphology of the element is fully automatic, regardless of the CAD system used. The appropriate automatic mechanisms are applied to each object (connectors, margin lines, offset, orientation, etc.), as well as optimised positioning in relation to the machine used.

Main software functions

Replace

Automatic and manual replacement of implant connections is included in MillBox. Several libraries of such connections are available to be inserted directly during CAM processing, replacing those present or missing in the CAD modelling files. The library, which can be fully customised by the user, allows specific strategies to be associated with the interface (shape and size of tools, technological parameters, type of machining, etc.).

Main software functions

Multiple sessions

MillBox allows the simultaneous opening of several work sessions. In addition, a “Progress Bar” is displayed in the Windows task bar, highlighting the progress of the calculation. Each MillBox session can work on different projects and with different machines, making the system extremely versatile and productive.